|

|

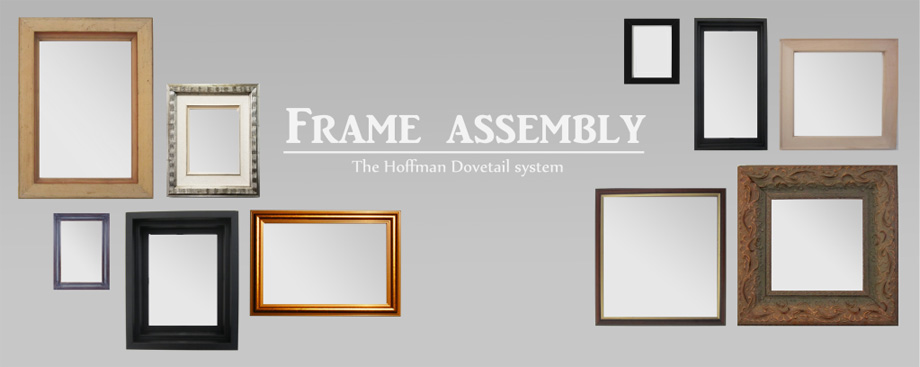

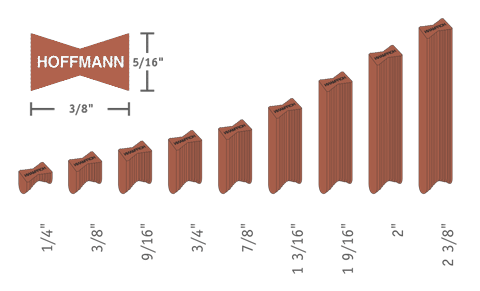

The joining system used to assemble these particular frames is called the Hoffmann Dovetail System. This joining system uses special shaped keys, made with ribbed, sloped sides, to connect the mouldings by creating a tight and perfectly aligned joint. The keys come in a bow tie shape and are available in different lengths and colours depending on the frame they are being used for.

This system is ideal for assembling very large picture frames; especially ones that are narrow and/or tall like shadow boxes, canvas floater frames, or extra large stretcher bar frames for artist canvases. It is ideal because it creates a stronger structure for these frames as well as it is safer if being transported as these keys are easy to assemble at home!

|

| Mouldings |

Keys |

Tools |

|

|

|

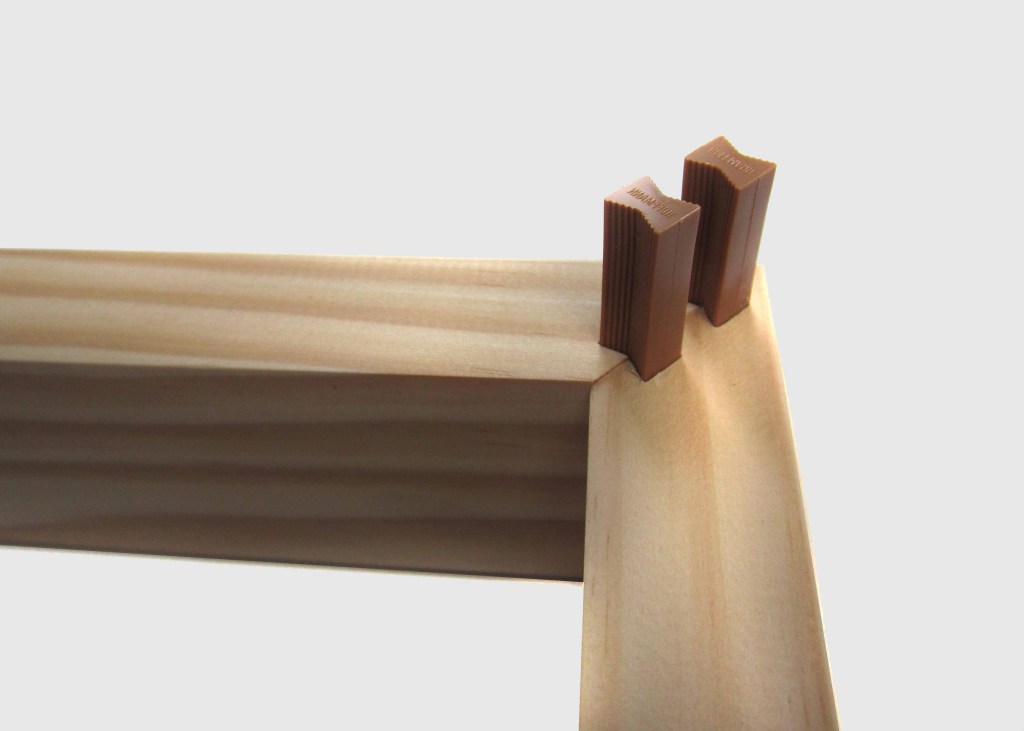

| You should have 4 or more separate frame pieces - a singular piece is otherwise known as a moulding. The Hoffman Routing machine creates a unique cut or keyway into the edge of the chosen moulding material. This key way will allow you to join two frame mouldings together by inserting a key into this cut out area. Dovetail Keyways (slots) are routed in all mitered ends. |

The joining system we use for these frames are called Hoffman Dovetail Keys. These keys are inserted to join the frame mouldings together, creating a tight and perfectly aligned joint. The Keys are a bow tie shape and they come in different sizes depending on the frame, please note we will send you the correct key for your frame.

|

To assemble your frame you will need your keys, hammer and we always recommend good quality wood glue. We may include screws and four flat corner braces for your frame if the frame is particularly large and requires additional support, for which you will also need a screwdriver. |

| |

| Step 1 |

Step 2 |

Step 3 |

|

|

|

| Grab your first molding and make sure the hollow end of the dovetail key is pointing up towards the sky. Repeat this with a second piece. |

Bring the two mouldings together and line up the adjoining faces, so you get a bow tie shaped hole pointing towards you. This should form a perfect 90 degree angle to form the first corner of your picture frame.

|

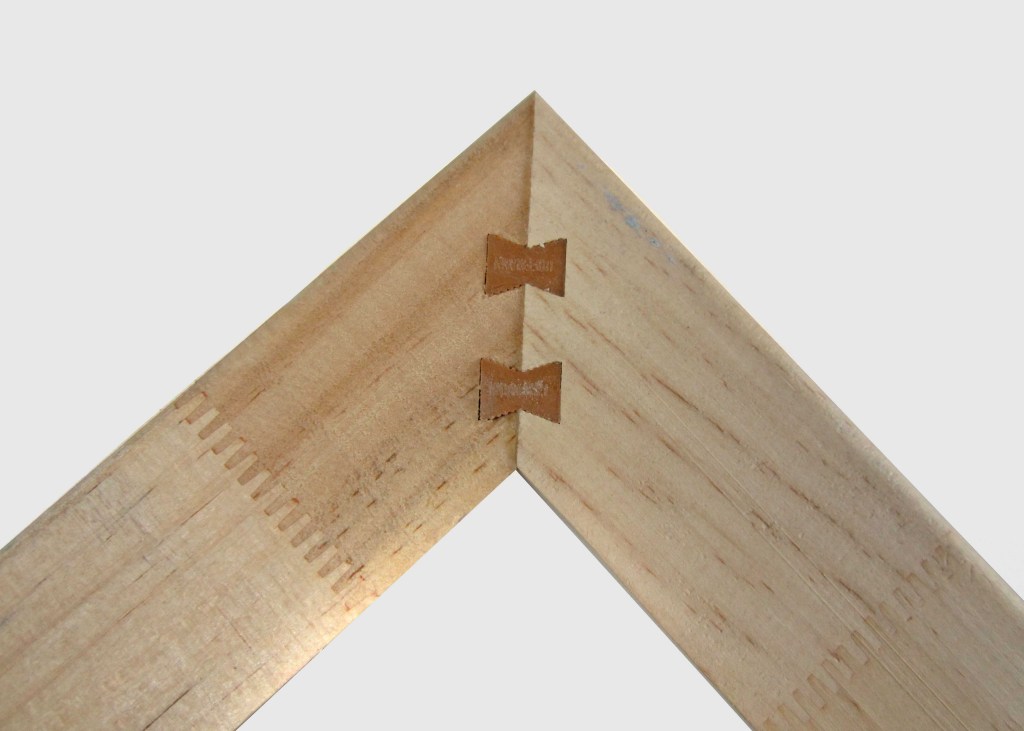

Whilst keeping the mouldings pressed together, grab your wood glue and add a little bit of glue to the inside of the bowtie shaped keyway. Then press your first key into the keyway, which will then hold the frame together. |

| |

| Step 4 |

Step 5 |

Step 6 |

|

|

|

| Once you have applied the wood glue, press the second key into the remaining keyway. |

Whilst holding the frame, grab your hammer and begin to tap down on the keys one by one.

|

The keys will slot perfectly into the keyway and bind the corner of your frame together, creating a tight seal that should look like this. |

| |

| Step 7 |

Step 8 / Optional |

Step 9 / Optional |

|

|

|

| Repeat steps 2- 6 for the remaining sides of the frame, attaching the remaining pieces of moulding one at a time. This will leave you with a finished picture frame! |

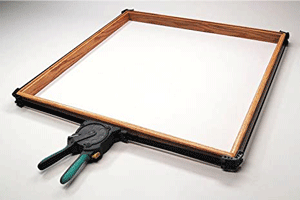

Strap Clamps / Band Clamps

For large frame sizes you may use a Strap Clamp to secure the frame parts in place and enabling even and uniform pressure on all sides when bonding. This will also minimizes the gaps on frame corners. Amazon Band Clamps |

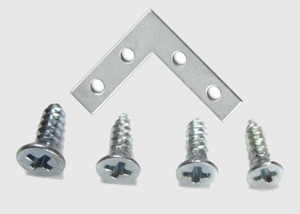

If your frame came with corner braces and screws please grab these for the next step. You should have 4 braces and 16 screws.

|

| Step 10 |

|

|

|

|

|

| If you choose to add corner braces after the glue is dried, place the corner brace flat over the top of the corner, this should fit best in between the two keys. With a screwdriver, screw in the frame onto the corner of the moulding. |

|

|

| More details: |

|

; ;

Before and after join |

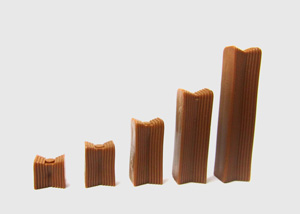

W2 Key Lengths |

| Dovetail Frame Assembly System FAQs: |

|

Q1 : What are the benefits of Dovetail system?

- Stronger join compare to v-nails

- Perfect for deep mouldings like shadow boxes

- Smaller shipping boxes when shipping extra large frames and saving on shipping

- Dovetail keys retain their shape and size no matter what the humidity, keeping your frame strong and properly aligned

Other benefits include faster assembly times, increased joint strength, improved precision, and the ability to disassemble and reassemble joints without damaging the components. They also eliminate the need for visible fasteners, enhancing the aesthetic appeal.

Q2 : What is a Dovetail key?

Dovetail keys are mechanical fasteners used to join two pieces of wood or other materials. They are shaped like a dovetail, a trapezoidal design that locks into a corresponding slot, providing a strong and precise connection.

The keys are made of a high strength plastic and made to very high tolerances to ensure a perfect fit in a properly routed slot. They come in different sizes (w0-w4), Lengths and even colors.

Hoffmann dovetail keys are a specific type of dovetail key produced by Hoffmann Machine Company. They are precision-made plastic or metal keys used to join materials with a unique dovetail slotting system.

Q3 : How are dovetail keys used in woodworking?

Dovetail keys are often used in woodworking to strengthen joints, align components, and add decorative elements to furniture and cabinetry. They can be inserted into pre-cut slots to join pieces securely.

Q4 : What materials are dovetail keys made from?

Dovetail keys can be made from various materials, including wood, metal, and plastic. The choice of material depends on the specific application and the desired strength of the joint.

Q5 : What are the common issues when using dovetail keys, and how can they be avoided?

Common issues include misaligned slots, incorrect key size, and loose fits. These can be avoided by careful measurement, using the correct tools, and ensuring precise cuts.

Q6 : How do I create dovetail slots for dovetail keys?

Dovetail slots can be created using a dovetail router bit and a router. The size and angle of the bit should match the dovetail key you plan to use. Precise measurements and careful cutting are essential for a perfect fit.

Q7 : Can dovetail keys be used with materials other than wood?

While dovetail keys are most commonly used with wood, they can also be used with other materials such as metal and plastic, provided the slots are cut accurately and the materials are compatible.

Q8 : Can dovetail keys be used in combination with other joinery techniques?

Yes, dovetail keys can be used alongside other joinery techniques, such as mortise and tenon, dowels, or screws, to enhance joint strength and stability.

Q9 : What sizes do Hoffmann Dovetail Keys come in?

Hoffmann Dovetail Keys are available in a range of sizes to accommodate different project requirements. The sizes are typically denoted by a letter and number combination, such as W-1, W-2, W-3, and W-4. Here’s a brief overview of the sizes offered:

Please note we do offer only W-2 size at this moment.

W-0

Smallest size, suitable for light-duty applications and smaller joints.

W-1

Slightly larger than W-0, used for small to medium-sized joints.

W-2

Medium size, commonly used for a wide range of woodworking and carpentry projects.

W-3

Larger size, suitable for heavier joints and structural applications.

W-4

Largest size, used for very heavy-duty applications and large structural joints.

Each size is designed to fit a corresponding slot made by Hoffmann’s routing machines. The choice of size depends on the thickness and type of material being joined, as well as the load-bearing requirements of the joint.

For precise dimensions and recommendations for specific applications, it is best to refer to Hoffmann’s product catalogs or consult with a Hoffmann representative.

|

|

| If you don't find the answer you're looking for here, please contact us. |

|

|

|

USA Giclee On Canvas, Fine Art Printing - Art Scanning & Reproductions - Handmade Oil Paintings - Custom Wood Panels, Metal Picture Framing - Block/Plaque Mountings, Large Format Dry Mounting & Lamination - Art Supplies: Stretcher Bars, Cradled Wood Panels and Artist Canvas - Collages On Canvas - Plexi/Acrylic Face Mounts - Block Acrylics, Fabric Printing, Dye Sublimation - Cityscape Skyline Prints, Resin, Photo Gifts and more...

|

|

© 2002-2025 - KeenART Media Ltd.

|

|

| |

|